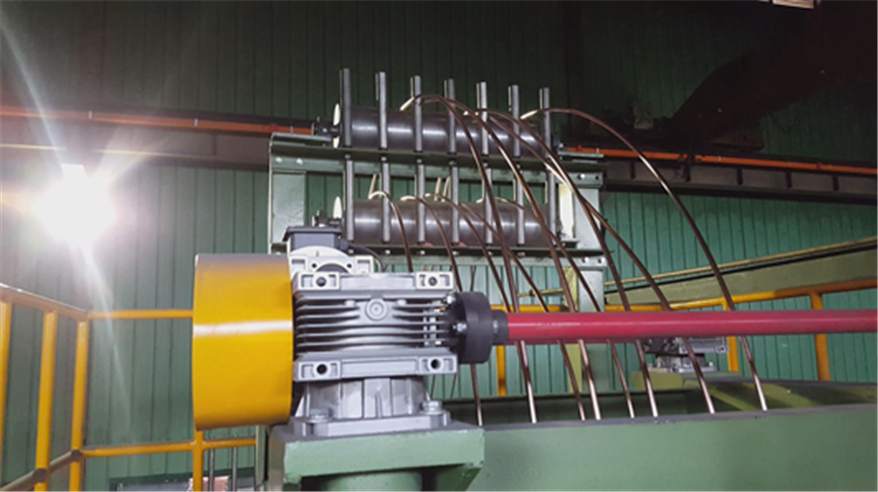

Up Casting line

Product Category

Product Category

- Copper Scrap solutions

- Aluminum recycling solutions

- Molten Aluminum solutions

- Rod casting & rolling

- Busbar production

- Strip production

- Profile extrusion

-

Flat&Round Wire processing

- High Speed Flat Wire Rolling Line

- Reels for Wires and Cables

- Copper CTC Continuously Transposed Conductor line

- Aluminum CTC Continuously Transposed Conductor line

- Paper Wrapping machine

- Drawing machine

- Aluminum Cladding Steel Wire machine

- Cross-linking Steam Room

- UV Radiation Cross-linking machine/Cable sauna for XLPE

- Continuous Extrusion machine

Related Product

Related Product

Craftwork flow

Cathode copper/Scrap copper → melting furnace → transition chamber → holding furnace → casting machine (crystal molding) → casting rod → take-up device → on sale or further producing

Put the cathode copper into the melting furnace of QL1 compounded furnace straightly. It will be melted into liquid by a frequency inductor. Then the liquid of copper smoothly pass through the transition chamber and will flood into the holding furnace automatically , and then it will be deoxidized by the charcoal covered. The liquid of copper will become a casting rod quickly by the crystallizer of the casting machine in the holding furnace. Then it will be hauled by the double-withdrawal roller of the casting machine. When the casting rod is hauled off, it will be led to take-up device.

| Copper Scrap Solution Comparison | ||||

| Process | Purity | Scrap Quantity | Product/Purity | Main Equipment |

| CCR | >95.2% | 10KT-50KT/annually | Rod/99.9% | Furnace, Casting/rolling, fume treatment |

| Adding to upcast after refinery | >96% | 1-3KT/annually | Rod/99.9% | Refining furnace, Up casting line |

| Adding to upcast without refinery | >99.5% | 5-20KT/annually | Rod/99.95% | Up casting line |

| Direct Electrolysis | >96% | <2 KT/a nnually | Cathode/99.95% | Electrolysis system, water purification |

| Anode Electrolysis | 90-92% | 5KT-150KT/annually | Cathode/99.97% | Refinery furnace, fume treatment,anode caster, electrolysis system, water purification |

More

More

More

More

More

More

More

More