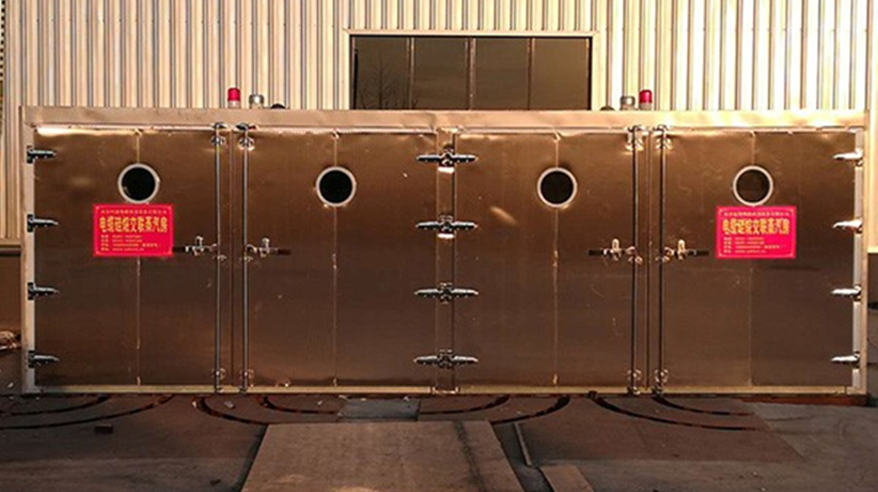

Cross-linking steam room

The design of the steam cross-linking room follows the principles of high operational safety, good insulation performance, homogeneous temperature and humidity, good air-tightness, automatic and accurate electronic control. Therefore, steam should be allowed to penetrate into each layer of the insulated single wire under constant temperature and constant pressure. In the gap between, the uniform cross-linking effect has been achieved:

- Convenient operation and high safety

Since the steam room adopts the omnidirectional pipeline steam heating scheme, the steam shows the characteristics of strong permeability and evenly heating. The steam cross-linking method can make the insulation cross-linking more balanced. At the same time, because the steam room is easy to operate, it can effectively avoid the damage on the cable due to crane lifting, reduce the hidden quality hazards of oxidation of cable conductors caused by water ingress.

- High working efficiency and short cross-linking cycle

Compared with water pool method, each pool can only store one wire core at a time, and each steam room can hold at least 4 wire cores at a time. The cross-linking time of each batch of wire cores can be shortened by about 20%. So, the daily amount of cross-linked coils has increased by 5 times compared with the past, speeding up the circulation of semi-finished products and greatly improving production efficiency.

- Automatic

The new steam room adopts solenoid valve thermostatic control and over pressure protection device. After setting the temperature and time, it can realize automatic temperature control without personnel on duty and effectively save labor cost.

Product Category

Product Category More

More

More

More