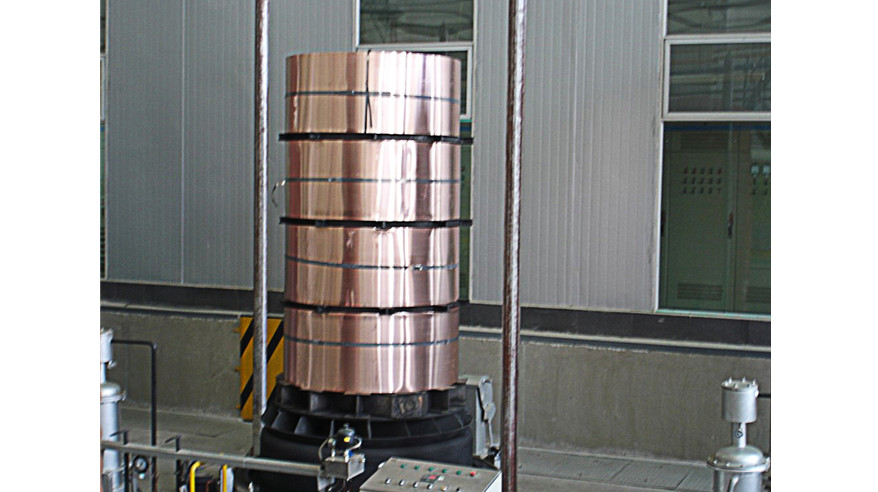

Bright (vacuum) bell annealing furnaces are to brightening and annealing the copper/copper alloy or steel strips, tubes, billets.

The bright annealing process for copper strips includes intermediate annealing process and final annealing process.

Copper strip intermediate annealing is to facilitate the next step of rolling: Reduce tension, soften copper strip

Copper strip final annealing is the last step of the rolling-pickling-annealing cycle process. After rolling to the target thickness, final annealing will keep the strip bright, reduce the grain size. Then strip will go to the slitting line to get the final product.

The annealing process for copper wire can increase the conductivity of the wire.

Main technical specification:

Temperature uniformity: ±5℃

Protection gas: N2 or H2

Loading capacity: customized

Product Category

Product Category More

More

More

More

More

More