1. Description of draw bench

The hydraulic automatic draw bench applies to draw forming and length cut of the copper busbar after extruding, The drawn copper bar has stable cross-sectional size, good dimensional accuracy, improved hardness, elastic limit and conductivity, and at the same time the machine increases the material utilization and greatly improves the surface quality of copper busbar.

2. Main technical parameters

|

1 |

Model |

YLB(Ⅰ)-50-10 |

||

|

2 |

Nominal drawing capacity |

50t |

||

|

3 |

Effective drawing length |

10m |

||

|

4 |

Specification of copper bar |

Width |

Max 200mm |

|

|

Thickness |

3~20mm |

|||

|

5 |

Drawing speed |

3~17m/min (the speed is up to 17m/min under low pressure) |

||

|

6 |

Return speed |

50m/min |

||

|

7 |

Install capacity |

125KW |

||

|

8 |

Compressed air |

0.8Mpa, 2m3/h |

||

|

9 |

Consumption of cooling water |

30m3/h |

||

|

10 |

Power supply form |

Three-phase four-wire |

||

|

11 |

Dimension |

Length (mm) |

23000 |

|

|

Width (mm) |

4500 |

|||

|

Height (mm) |

2200 |

|||

|

12 |

Requirements of the length of the workshop (mm) |

36000×5000 |

||

3. Main component

3.1. Pay-off stand

3.2 Guide stand

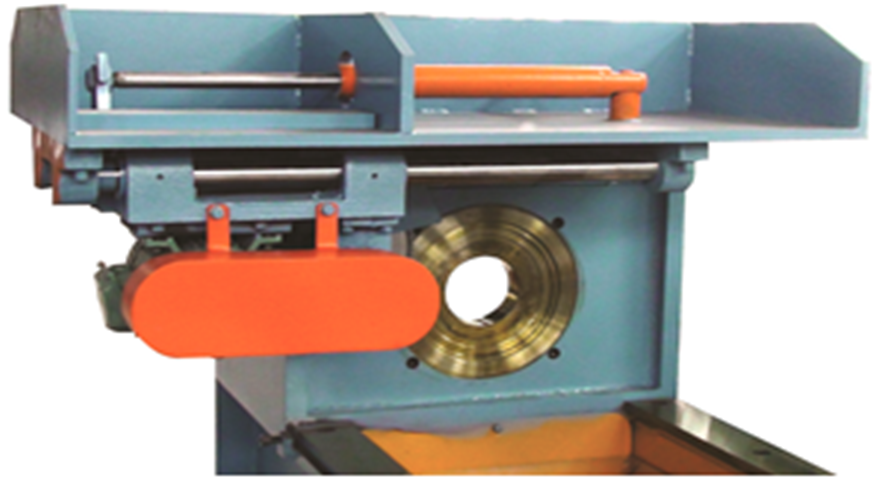

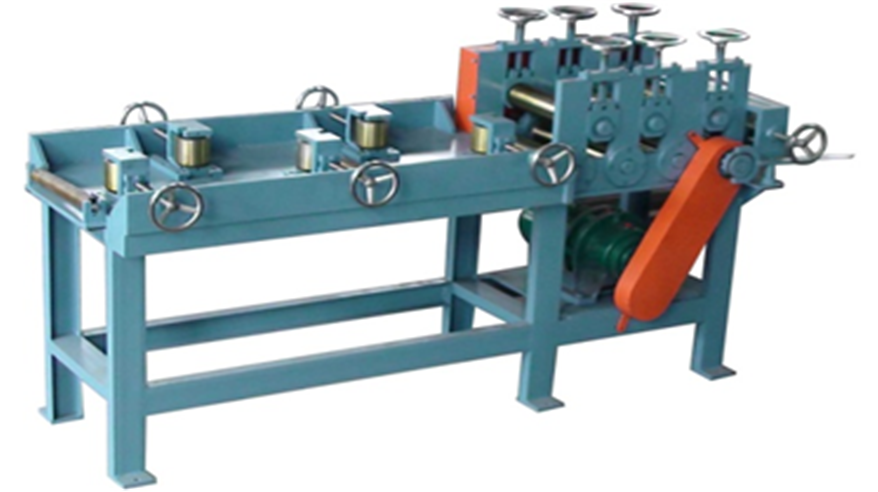

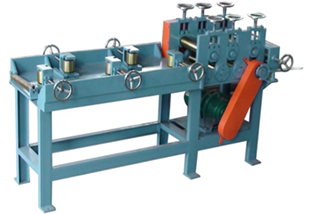

3.3 Straightening and feeding machine

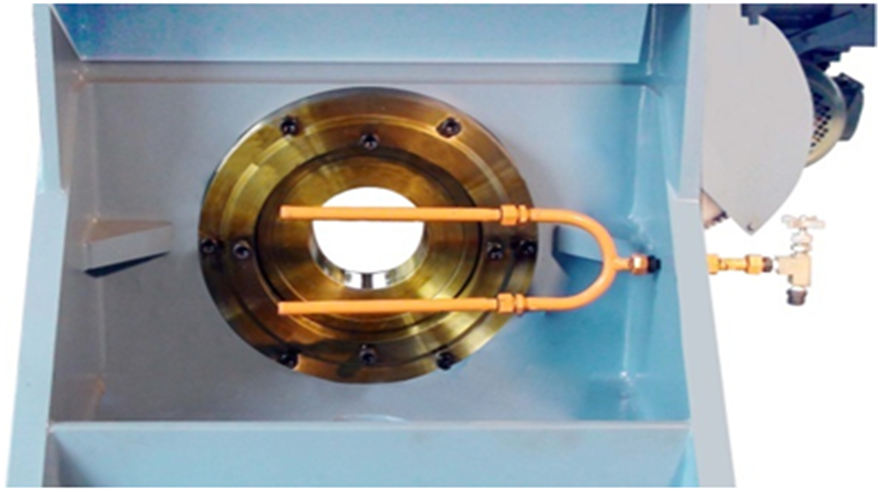

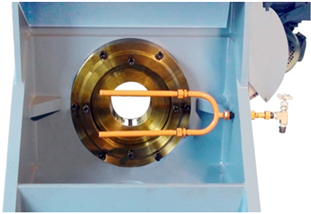

3.4 Cooling and lubricating system of die

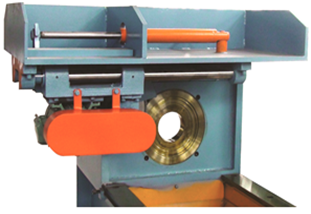

3.5 Main drawing machine

3.6 Transport mechanism

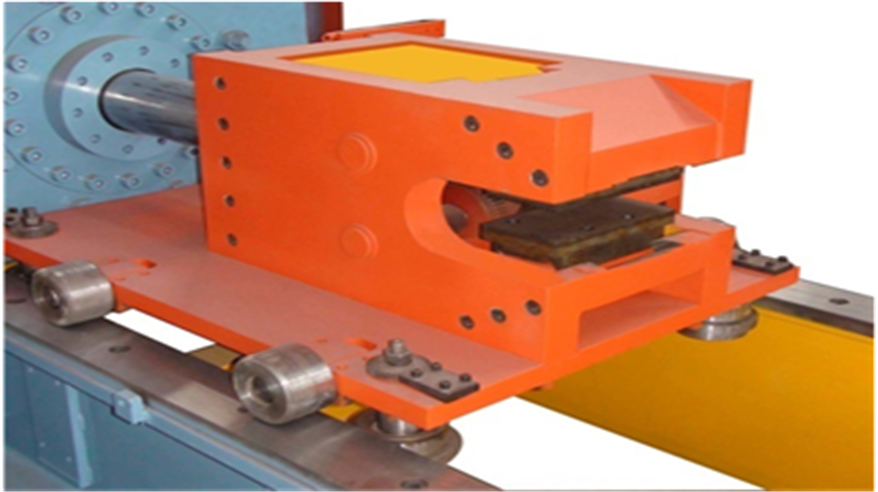

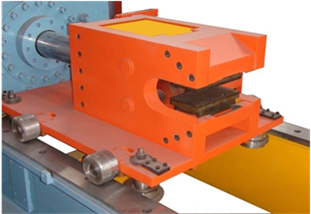

3.7 Final product cutting machine

3.8 Fix-length roll table

3.9 Stacking device

3.10 Hydraulic system

3.11 Electrical control system

3.12 Pointing machine

Product Category

Product Category More

More

More

More