Aluminum dross, a byproduct of aluminum production, presents a significant environmental and economic challenge. Managing and processing aluminum dross efficiently is crucial for reducing waste and maximizing the recovery of valuable aluminum metal.

Beijing Holland keeps exploring various aluminum dross treatment methods and different application scope. Cost-effective and high recovery rate solutions mean better profits and ROI to our clients, in which Beijing Holland is always persisting.

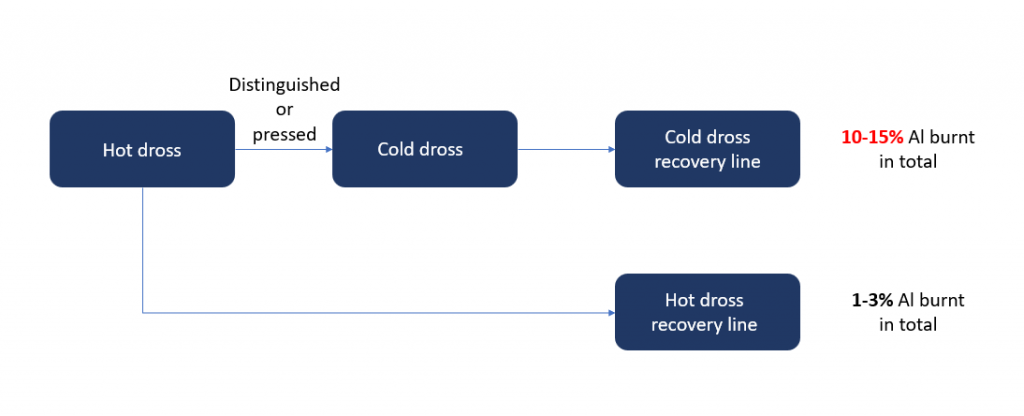

We offer solutions for recovering both hot & cold dross. However, the Aluminum burnt during cold dross recovery process is over 10% higher than that is during hot dross recovery.

For more data & quotation, contact us now!

| Models | Size (cm) | Blade rotate speed (r/min) | Capacity (kg) |

| LY-130 | 180*180*350 | 18 | 700 |

| LY-110 | 150*160*330 | 22 | 500 |

| LY-90 | 130*140*270 | 22 | 300 |

| LY-70 | 110*110*250 | 22 | 200 |

| LY-50 | 100*100*200 | 22 | 100 |

For more data & quotation, contact us now!

Al dross separator with movable pot

Suitable for Al dross from Al smelters and resmelting process.

For more data & quotation, contact us now!

![]()

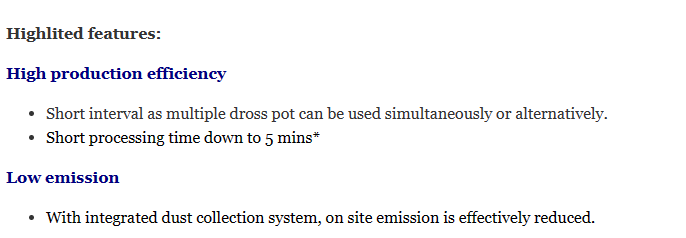

Rotary furnace

Designed for Al cold dross & scrap recycling process. Burner can be added as optional auxiliary equipment.

For more data & quotation, contact us now!

![]()

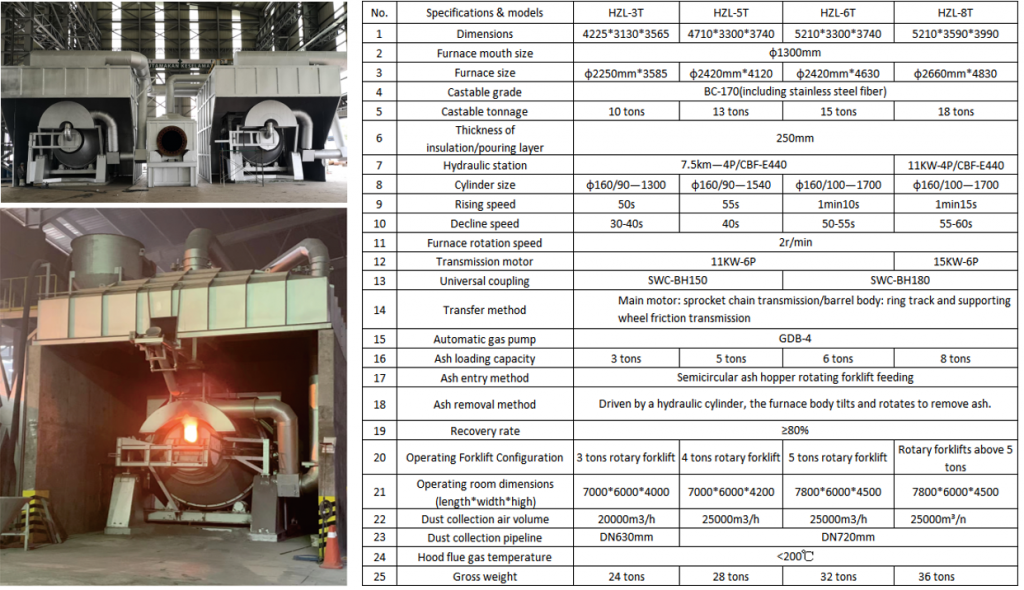

We suggest all hot secondary dross left after the first processing step shall go thourgh the cooling, screening & ginding (optional) process, to ensure on-site safty & maximizing recovery rate.

Cooling, screening & grinding machine

For more data & quotation, contact us now!

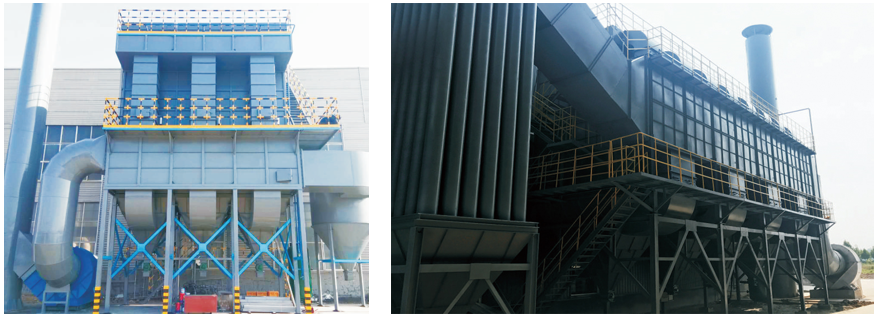

Dust collection system

For more data & quotation, contact us now!

Product Category

Product Category More

More

More

More

More

More