Composed transport conductor:

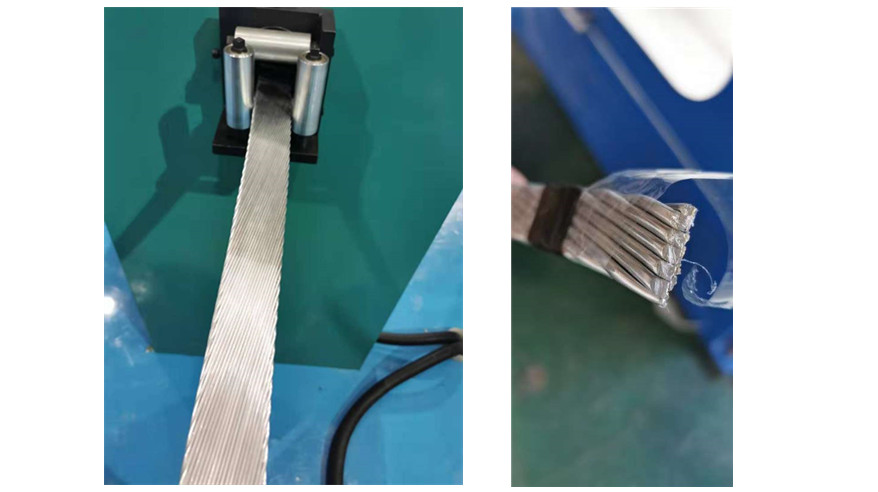

Transposed conductor refers to the combination of a certain number of enameled copper flat wires into two rows with wide surfaces that are in contact with each other, and the upper row and lower row enameled wires are transposed in the same direction along the narrow surface, and electrical insulation paper is continuously tightly wrapped into multilayer.

The windings of large power transformers adopt transposed wires, which can greatly reduce load loss, reduce the temperature rise of winding hot spots, improve the mechanical strength of the windings, make the structure more compact, and the coil processing is easier, so the transposed wires have been used in large power transformers once they came out. It has been widely used in winding design and manufacturing.

I. Application:

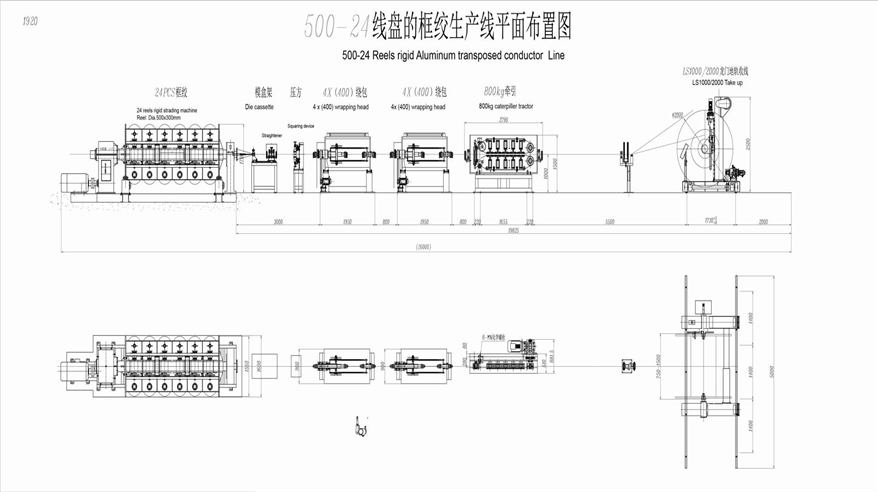

The line is mainly used to produce Aluminum continuous transposed conductor. The product is widely used on High voltage and Ultra-high voltage reactor in power transmission field.

II. Processing flow:

Rigid stranding—Transposed — Squaring — Lapping — Traction — Length counter — (insulation checking) — Take up

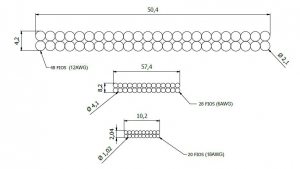

III. Product design requirement (final product section):

Product Category

Product Category More

More

More

More

More

More