Billet casting process: Melting furnace→ Aluminum rod casting machine→ Aluminum rod cutting→ Aluminum rod homogenization treatment → automatic stacking

Aluminum billet use: Through the horizontal aluminum extrusion machine, aluminum profiles and special grade aluminum rods are extruded.

Casting machine Application: Casting is to cool and cast the aluminum liquid into round casting rods of various specifications through a deep well casting system under certain casting process conditions. The vertical semi-continuous casting machine includes a casting platform, lifting table, transmission device, ingot base, water cooling system, and control system.

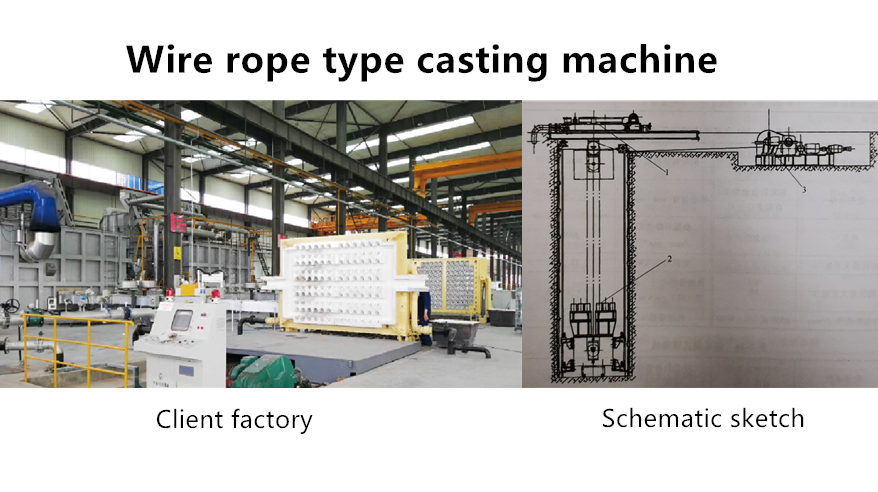

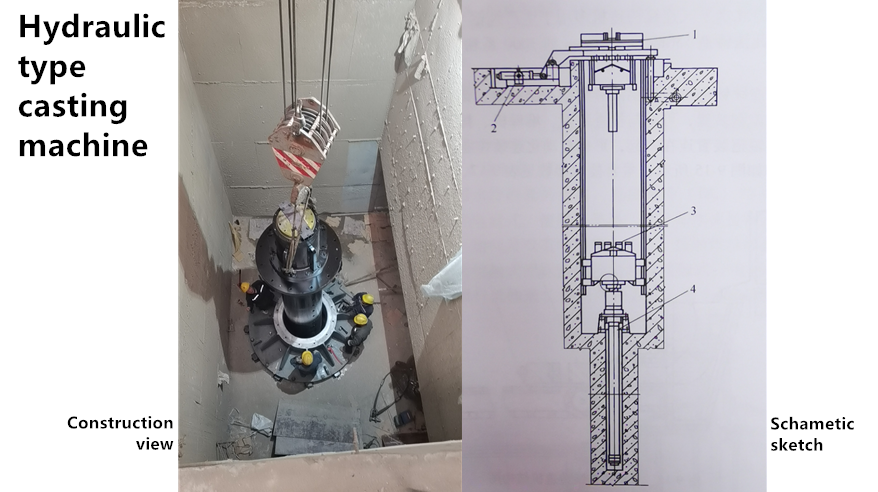

The casting machine has two types: wire rope type and hydraulic type.

Wire rope type:

The hoisting mechanism is used as the transmission device, and the base is raised and lowered by winding the wire rope through the reel (winch), and the speed can be adjusted steplessly by the machine or the motor during casting.

Advantages:

1)It has a simple structure, low cost, and is widely used;

2) It is easy to operate, suitable for casting round ingots and flat ingots of various specifications.

Hydraulic type:

It uses a hydraulic oil cylinder as a transmission device, piston rod as a starter to pull out the ingot from the crystallizer. It can adjust the casting speed by changing the pressure in the cylinder below the piston.

Advantages:

The casting speed can be adjusted arbitrarily, the operation is stable, the surface quality of the aluminum rod is high, and the internal crystal structure is uniform and consistent;

Send us your need! We can provide the most suitable scheme for you by knowing your project details.

Product Category

Product Category More

More

More

More